Avery Dennison, Israel

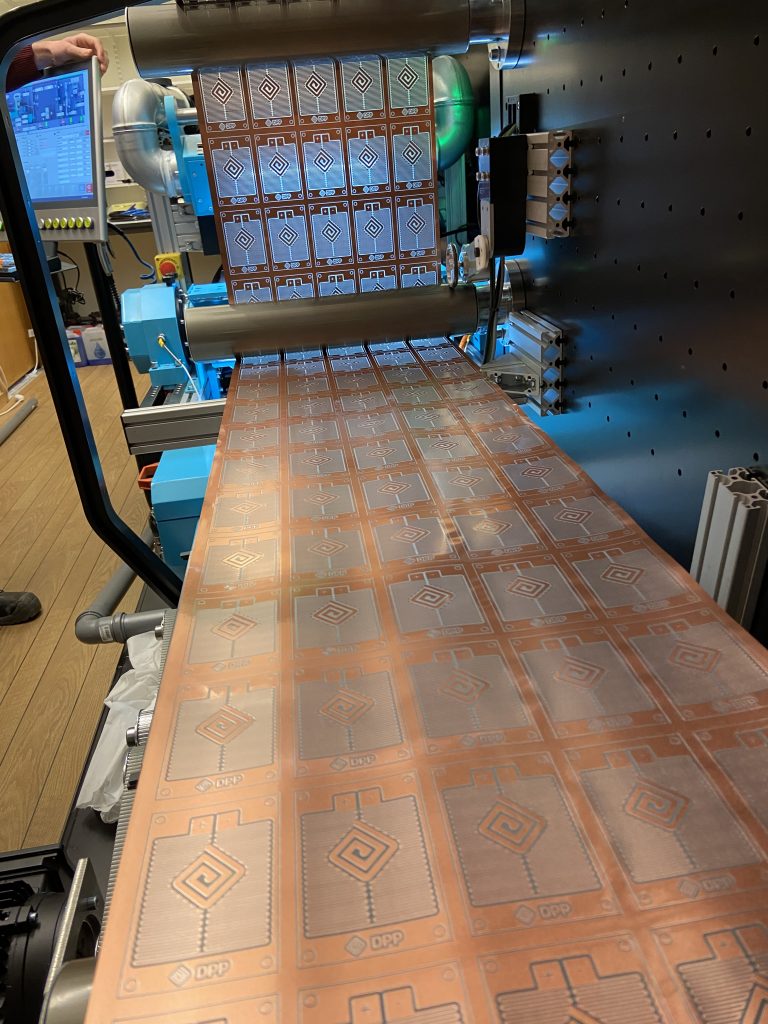

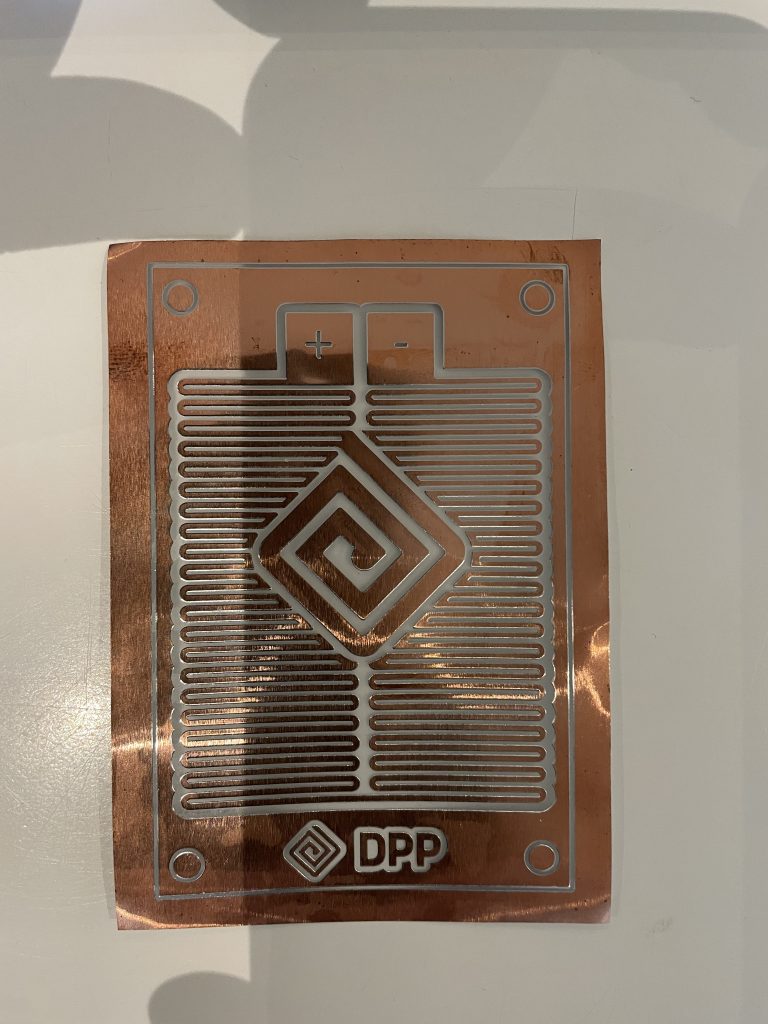

Combination of two novel technologies in flexible films to open up new applications in circuitry design and sensor making.

Copper foil is well-established in the electronics industry, but cost constraints drive the search for alternatives. Avery Dennison combines two technologies in to create an alternative for traditional copper foils. The first technology, Copper Skin™, enables a copper coating on aluminum foils. And the second one (DPP) allows the possibility to mechanically remove and reduce the foil thickness selectively at dedicated areas. Once current is fed into the circuit, due to the electrical design of current flow and resistivity, the conductors are heated to the specific temperature required by the application. The combined technologies, in this case, saved ~50% of the cost of a similar structure produced using a conventional wet chemical process.

Purpose

- Create a cost-efficient alternative to traditional copper foils with a high conductivity

- To reduce the total energy consumption, no toxic chemicals, and recyclable-friendly residuals

Target Group

- Healthcare

- Automotive

- Consumer Electronics

- Communication

Benefits

- Upscaling

- Recyclable-friendly residuals

- Relatively low production cost

- Low environmental impact

Printed Electronics Components

- Conductive path

- Printed heater

- Printed antenna

- Printed sensor