Rise (Sweden)

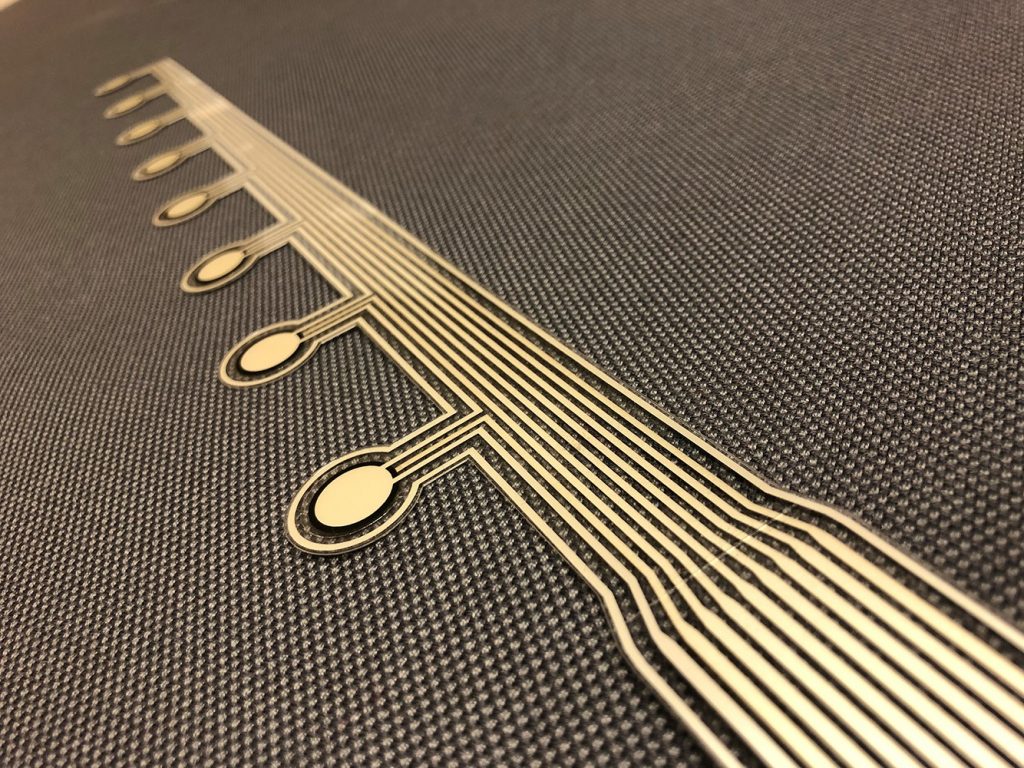

There is a current healthcare need for improved prosthetic socket fit provision for the masses using simple to manufacture sensors that can measure pressure and also shear and loss of friction (a major cause of tissue damage and skin lesions). There is also a need to address society’s increasing concerns regarding the environmental impact of electronics. Demonstrator: Printed low-cost QTSS wearable flexible more enviro-friendly pressure, shear and loss of friction sensors for dynamic Prosthetic fit monitoring for leg amputees.

Printed low-cost PET QTSS wearable flexible pressure, shear and loss of friction sensors are designed to be adhered inside a leg amputee’s socket. The QTSS multi-point pressure sensing ink strips are printed and then assembled and are trimmable to fit all shapes and sizes of sockets.

Target Group

- Healthcare (limp amputation)

- Could also be easily adapted to address other applications and markets requiring conformable low-weight affordable pressure and shear/loss of friction monitoring.

Attractiveness of the Product

- Ultra light: perfect for situations requiring monitoring whilst remaining unobtrusive

- Flexible: QTSS – Quantum Materials are ideal for sensing on ‘curved’ surfaces

- Ultra-thi: allowing seamless integration into surfaces without changing shape or thickness

- Easy-to-install: integrated adhesive. Simple to adhere to inside of socket

- Low cost: simpler and easier to manufacture for the masses

- More Enviro-friendly and energy efficient

Printed Electronics Components

- Printed sensor (pressure)

- Printed electrode

Funding Source

H2020-ICT EU project