Flexoo, Germany

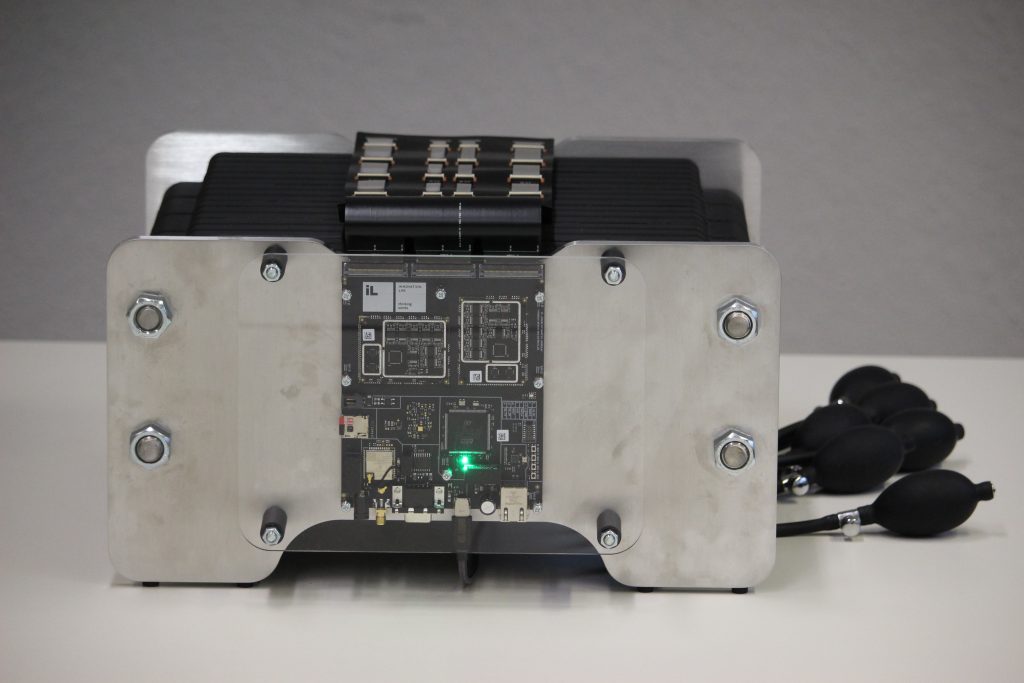

BaMoS offers a complete battery monitoring solution, including the sensor foils, electronics to gather and process the captured data, and software for live visualization, storage and analysis of the data.

A key parameter for people buying electric vehicles is the performance of the battery in terms of power and durability. During the charge and discharge cycle, a battery cell constantly changes its volume and temperature, it “breathes”. Excessive changes in these parameters lead to degradation and reduced battery lifetime. BaMoS uses ultra-thin printed pressure and temperature sensors to capture detailed battery data down to the individual cell level, which can be used by R&D teams to extend battery lifetime by up to 40%. BaMoS prototype shows in real-dimension and real-time the measurement of pressure distributions inside the battery of an EV.

Purpose / Benefits

- Prevent overcharging

- Perform cell balancing – which maximizes battery capacity and lifetime

- Cycle lifetime (the number of charge/discharge cycles a battery can complete in its life) can be improved by 30 to 40 per cent

Organic & Printed Components

- Printed dielectric / insulator

- Printed electrode

- Printed sensor

Target Group

- Automotive

- Readout Electronic

- Computer

- Cables

- FFC Connectors