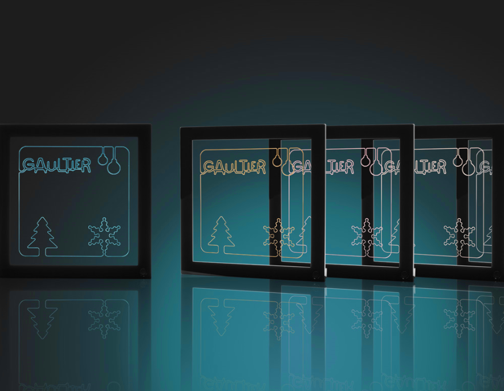

Normandy Coating, France

Illuminate the name of a perfume brand on the lid of the packaging box by offering the greenest possible solution by reducing the number of components.

The goal of Normandy Coating is to highlight the pictograms and text of the lid of a perfume bottle by bringing light into the edge of the polycarbonate part of the lid to capture it in the pictograms and the text. This lid is made of injected plastic (PC/ABS) in addition to a transparent polycarbonate part. A classic construction (PCB) would require at least 14 components(1 PCB, 3 leds, 3 resistors, 4 wires, 2 battery connections, 1 switch) plus batteries. This flexible printed PCB reduces the number of components to four (flex PCB, 3 LEDs) in only one assembly.

Purpose

- To bring light into a box of perfume bottles and to highlight the pictograms and the text of the lid

- Replace classical construction and reduce the construction to 4 components (3 LEDs, flex) with only one assembly operation

Target Group

- Printing and Packaging

Benefits

- Reduced assembly time

- Weight loss compared to a standard PCB

- Reduction of the environmental footprint

- Cost reduction

Printed Electronics Components

- Conductive Path

- Printed switch

- Printed interconnection

- Printed adhesive

- Printed resistor