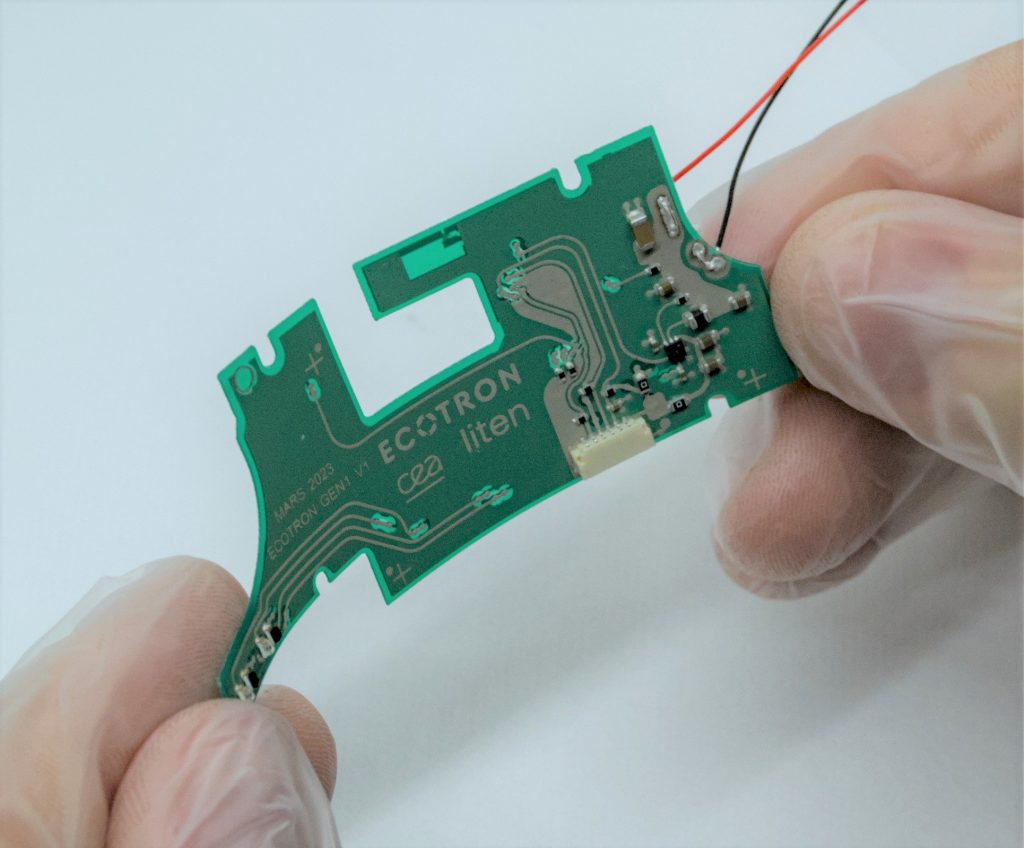

CEA Liten, France

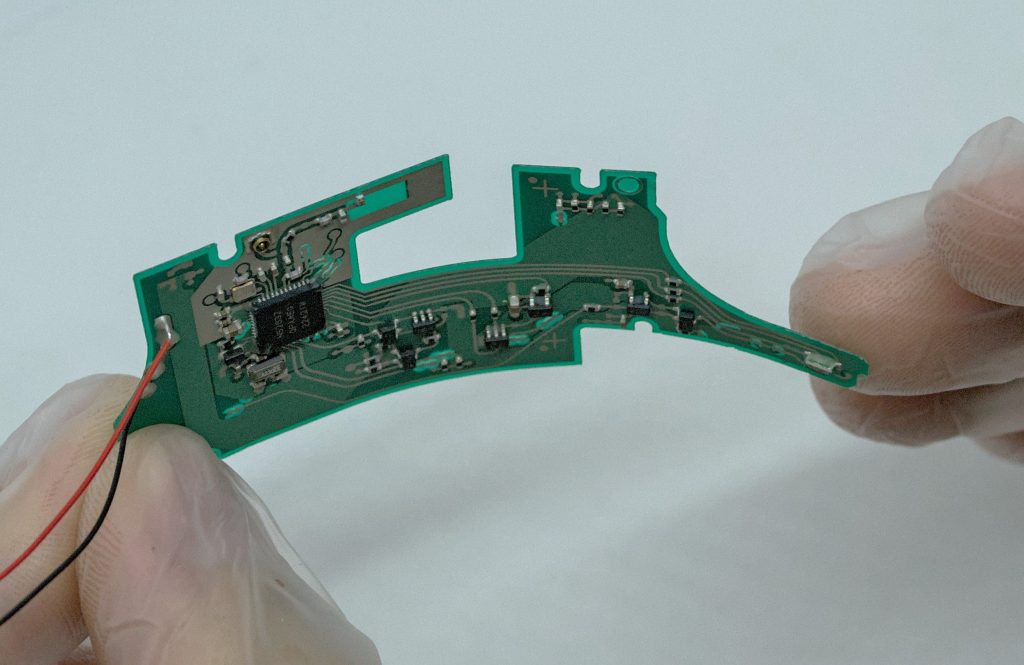

This demonstrator showcases a multilayer, double sided flexible printed PCB as a replacement for a classical rigid PCB keeping the same form factor.

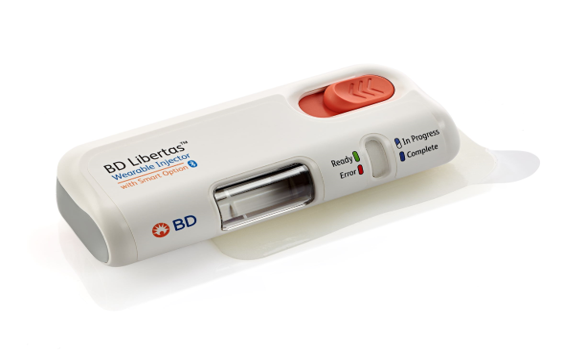

This demonstrator tackles the question “can we replace classic rigid PCBs with more environmentally friendly printed flexible PCBs without compromising the performance, form factor and complexity?“ This demo is a proof of concept that a PCB with wireless communication, analog and digital functions can be fabricated using flexible printed electronics technologies. Medical device use case: on-body subcutaneous drug delivery system.

Purpose

- Opens a perspective for replacing even more complex rigid PCBs that includes higher number of metal layers, with PE technology

- Chemical free and additive manufacturing process and organic (recyclable) materials use

- In further demonstrator generations in the project, the substrate, inks, and components assembly will be replaced with more sustainable materials developed in the project

Organic & Printed Components

- Conductive path

- Printed interconnection

- Printed dielectric / insulator

- Printed through-substrate vias

Target Group

- Healthcare

- Wearables

- Consumer Electronics