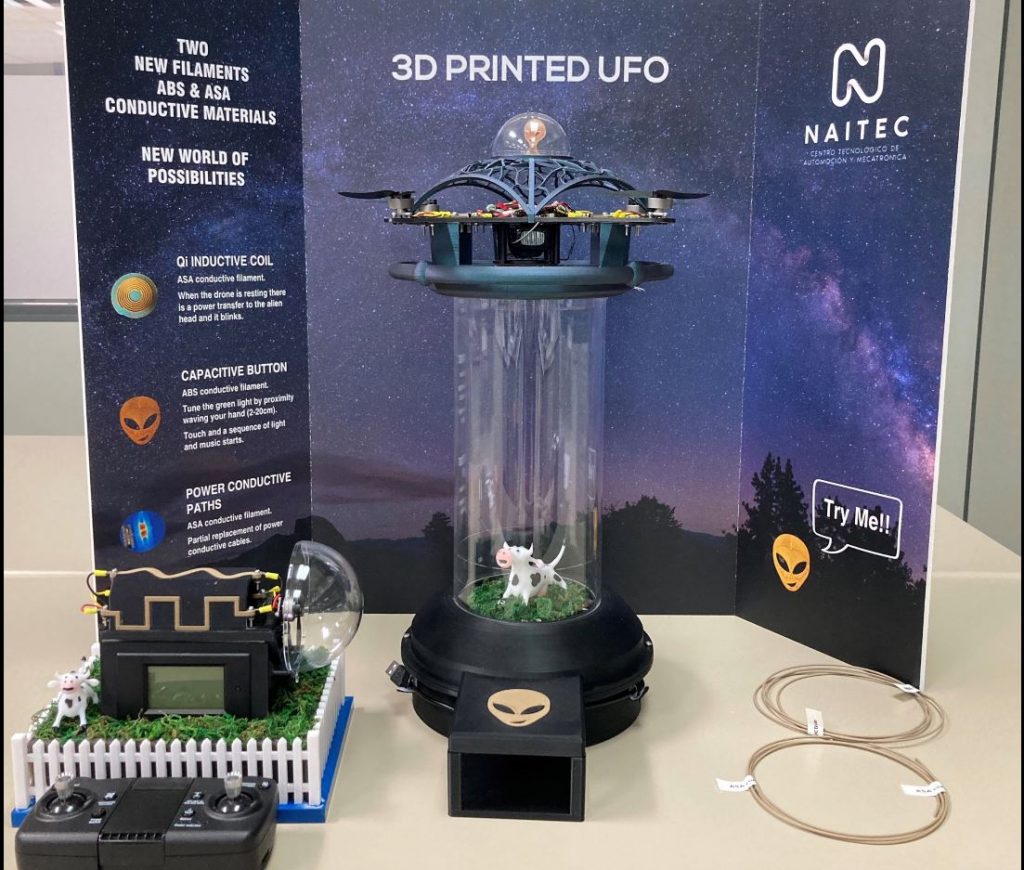

NAITEC, Spain

A flying 3D print UFO using conductive and conventional plastic filament.

The 3D Printed Ufo by NAITEC shows the capabilities of two new conductive filament, developed by NAITEC as substitution of conventional conductive material. The purpose is to 3D print both, the main body and the printed electronics, of a fully functional UFO in one single printing process. The filament is a polymer based and not metallic one, which can be printed in a desktop printer without additional debinding and sintering. The UFO is fully functional, it can fly and turn on the electronics components included: capacitive button and inductive charge. This technology can be used for lightening, driving force for a lot of enviromental impact benefits. The 3D Printed Ufo consists of a 3D printed inductive spirem, a platform base with a capacitive button and a drone and external arm that partially replaces conductive cables by conductive filament 3D printed paths.

Purpose

- Show two new conductive filament to the 3D printing market that are polymer- based

- Show the capabilities as substitutive of conventional copper wires or components

- This technology can be a driving force for many environmental impact benefits

Target Group

- 3D Printed Products

- Automotive

- Consumer Electronics

Benefits

- This filament does not need debinding or/and sintering processes and can be printed in cheap desktop printers.

- Simplicity of manifacture of 3D printed objects with conductive parts

- Can be printed by conventional and cheap 3D desktop printers without any post-processing

- Can be produced with different types of polymer‒The same filament can be used for the fabrication of different passive electronic elements by one process step

Printed Electronics Components

- Conductive path

- Printed capacitive switch

- Printed interconnection

- Inductive coil