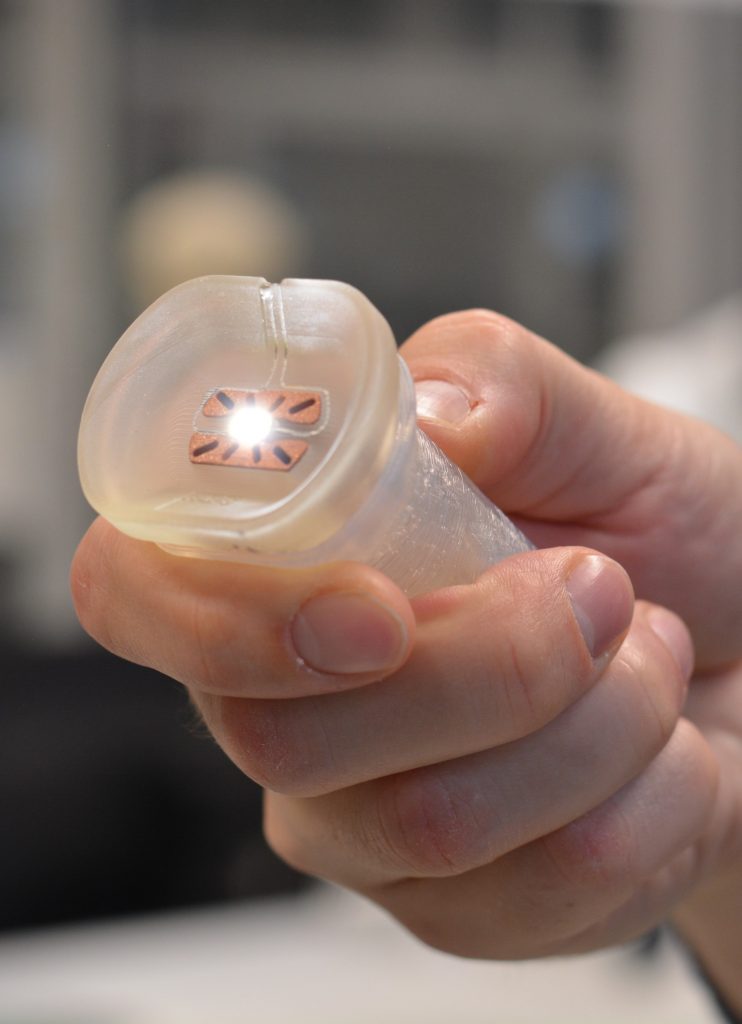

FAPS, FAU Erlangen-Nürnberg, Germany

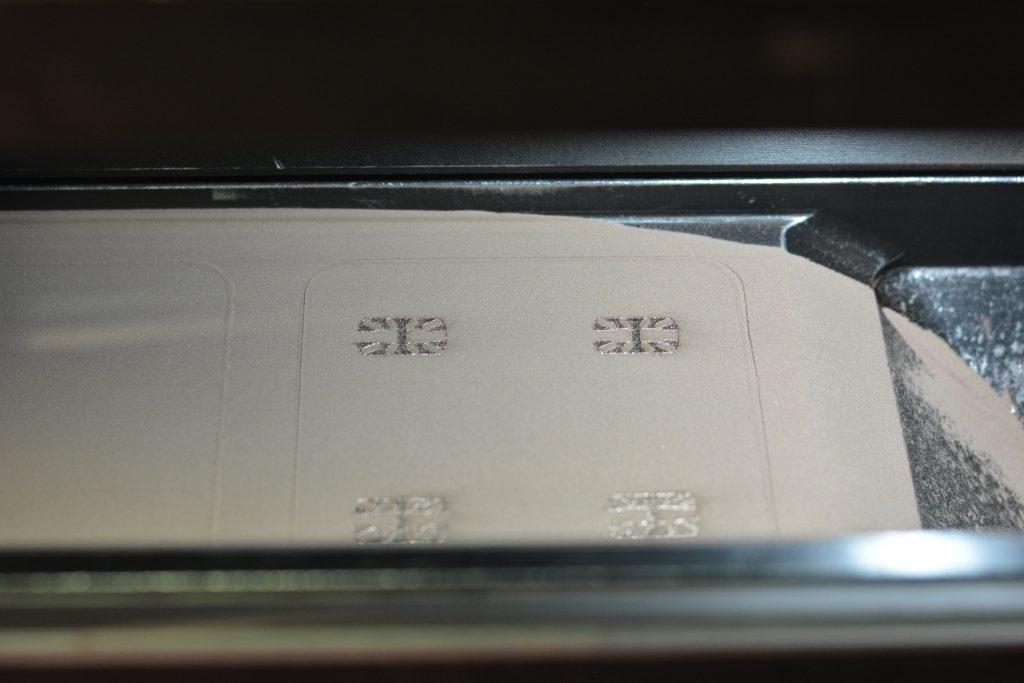

The flashlight demonstrator combines various state of the art manufacturing processes in one product. The base body is manufactured using stereolithography, while the conductor tracks are printed with conductive silver paste using Piezojet. The silicone shell, which provides a comfortable hand feel and protects the electronics, is manufactured using liquid additive manufacturing, which is a very young process. An additively manufactured heat sink dissipates heat energy from the LED and increases its service life.

The flashlight consists of a base body, which is manufactured with a high precision stereolithography machine. Electronic conductor paths are then printed onto this base body using Piezojet in a 5-axis motion platform. In addition, further components for the control system, power supply and an LED as light emitter are placed. The flashlight is powered by a button cell and can be switched on and off via the built-in button. Finally, the handle of the flashlight is covered with an additively manufactured and biocompatible silicone sleeve, so that the flashlight fits comfortably in the hand.

Purpose

- Teaching and training of students at our university in the field of printed electronics can be taken to the next level. New technologies can be learned practically and not only theoretically and will

- Increase interest in printed electronics and to inspire students for the technology

Organic & Printed Components

- Printed interconnection

- Conductive path

Target Group

- Consumer Electronics

- Automotive

- Healthcare