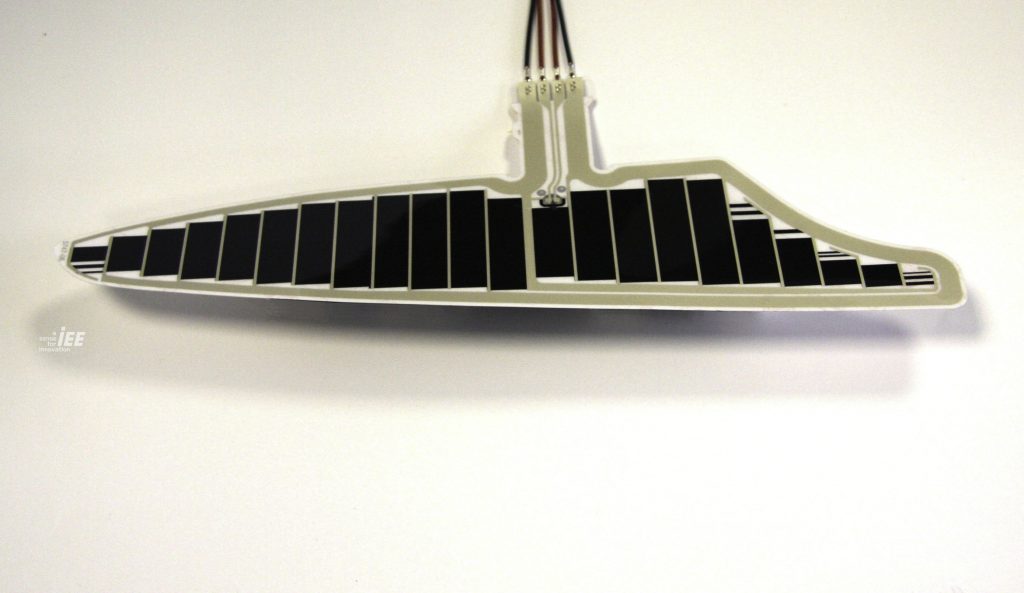

A key trend in the automotive industry is the tendency for motor vehicles to become “smarter” and to have more and more information interfaces with the driver or passenger, all while being lightweight and taking up very little installation space. As more operating functions, including eventually driving itself, are carried out by on-board computers, the driver/passenger will have even more interaction with information and entertainment systems in the car. The trend is for these interfaces to be integrated into the car interior, which has led to flexible and conformable touch sensors and displays, enabled by OPE to be used in modern cars. Among current applications, seat occupation detectors that enable the detection and classification of vehicle occupants for important safety functions are the most inconspicuous parts facilitated by printed electronics. OLED technology is already implemented commercially in cars, both for interior displays and for taillights. A key selling point for OLED in this case is the freedom of design, which is not feasible with any other light source. Furthermore, the transition to electric vehicles requires new heating concepts for the automotive interior where printed heating foils are that can be integrated directly beneath the surface represent an ideal solution.

Many of these examples can also be applied in aviation and public transportation modes. Printed electronics has already become an integral part of the aviation industry. Sensors, lighting and other elements made with state-of-the-art printing technologies are now being used in planes. There are for example printed sensors integrated in turbine blades which detect bird strikes. In case a plane is hit by a bird, serious damage or even engine failures can occur. With this sensor technology it is possible to easier as well as quicker recognize and locate the damage, enhancing safety and reducing cost. Furthermore, some airplanes are already equipped with electrochromic windows which can automatically or manually adapt its shade from transparent to jet black. Due to this technology shutters are no longer required, which enhances user experience and reduces thickness and weight.

Application Examples

Flexible and printed electronics has successfully entered important industry sectors. From consumer electronics, internet of things and healthcare to automotive, smart packaging and buildings: Printed electronics is now globally being applied in numerous products and industries. The focus industries OE-A is looking into, which are also represented in the OE-A Roadmap, can be found below.

OLED taillight

OLED taillights emit a very homogeneous and precise light, while the modules are very thin and flexible. Thus, they provide a very efficient and lightweight light source.

Heating foil

The coming age of e-mobility requires new heating sources, since the excess heat from the combustion engine cannot be used anymore. Printed heating foils enable a flexible and inherently safe integration of heating elements.

Head-up display

Transparent OLED displays enable the integration of head-up displays directly into car windows. This helps to provide more information to the driver, without distracting him from the traffic.