VTT, Finland

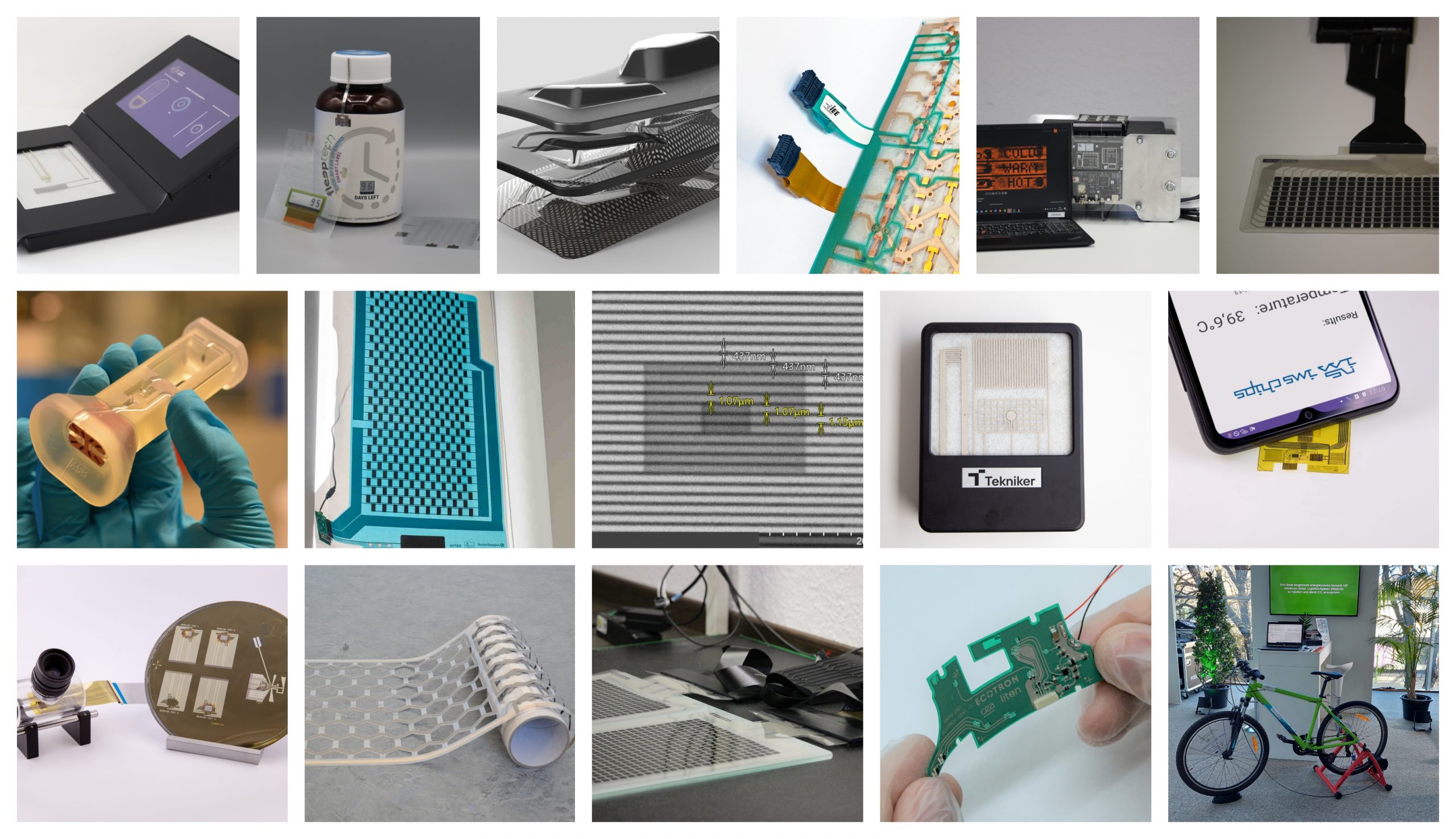

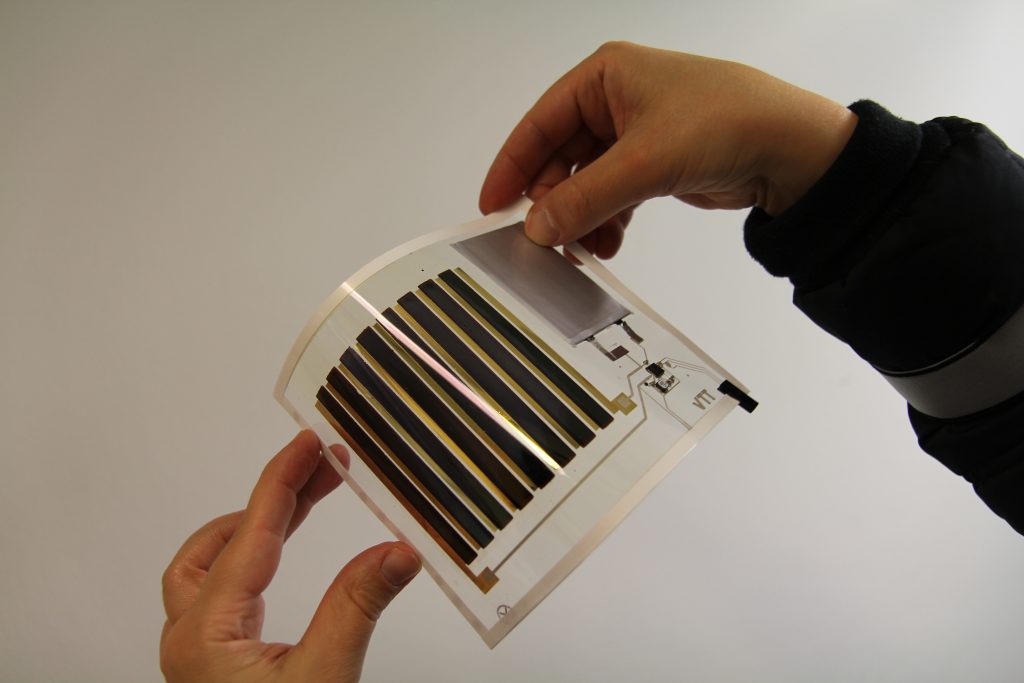

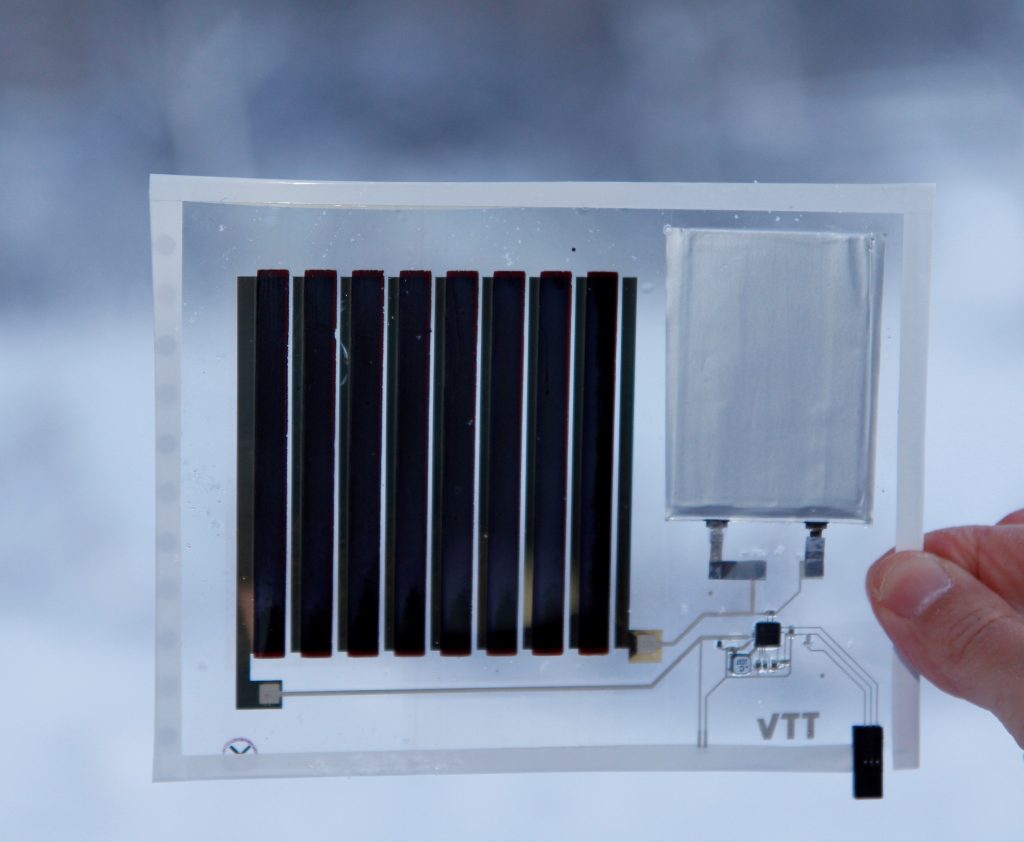

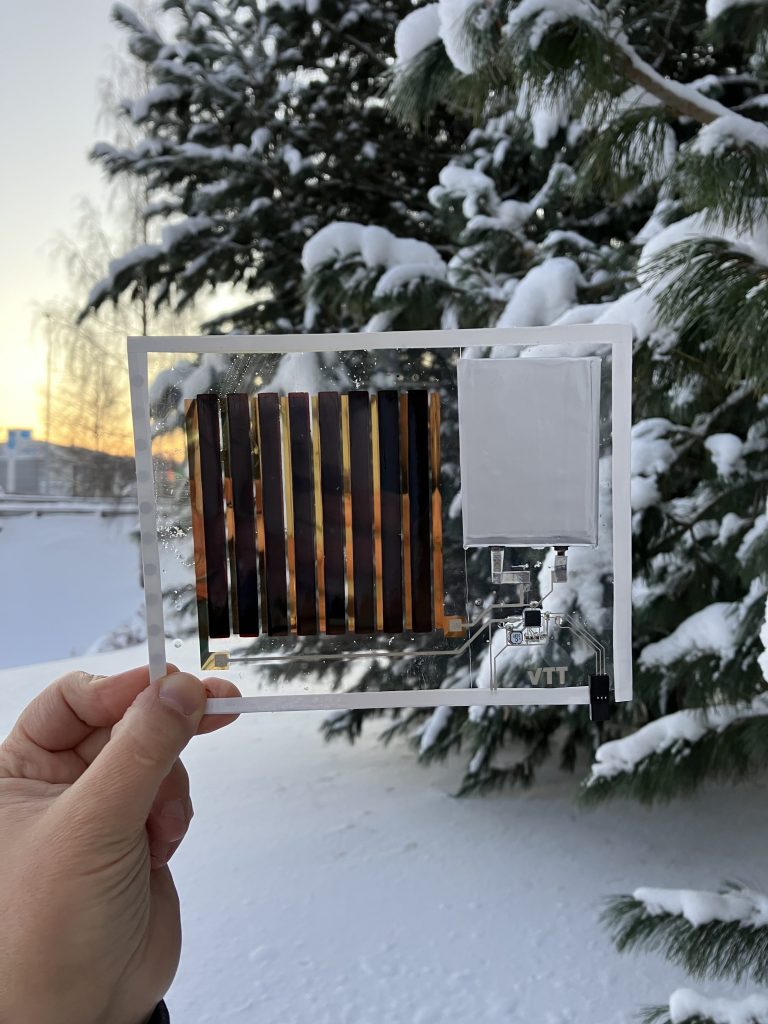

The perovskite PV based energy system is a lightweight, flexible platform utilizing both sides of the substrate.

A fully roll-to-roll manufacturing process of through-substrate vias enabled double-sided printed electronics. The energy module by VTT consists of a photovoltaic module on one side, and a battery on the other side of a flexible plastic substrate. The processing was done in a combination of roll-to-roll and sheet based processes to enable high degree of integration of the flexible perovskite solar module. This is a first for a double sided hybrid system with a gravure printed perovkite layer.

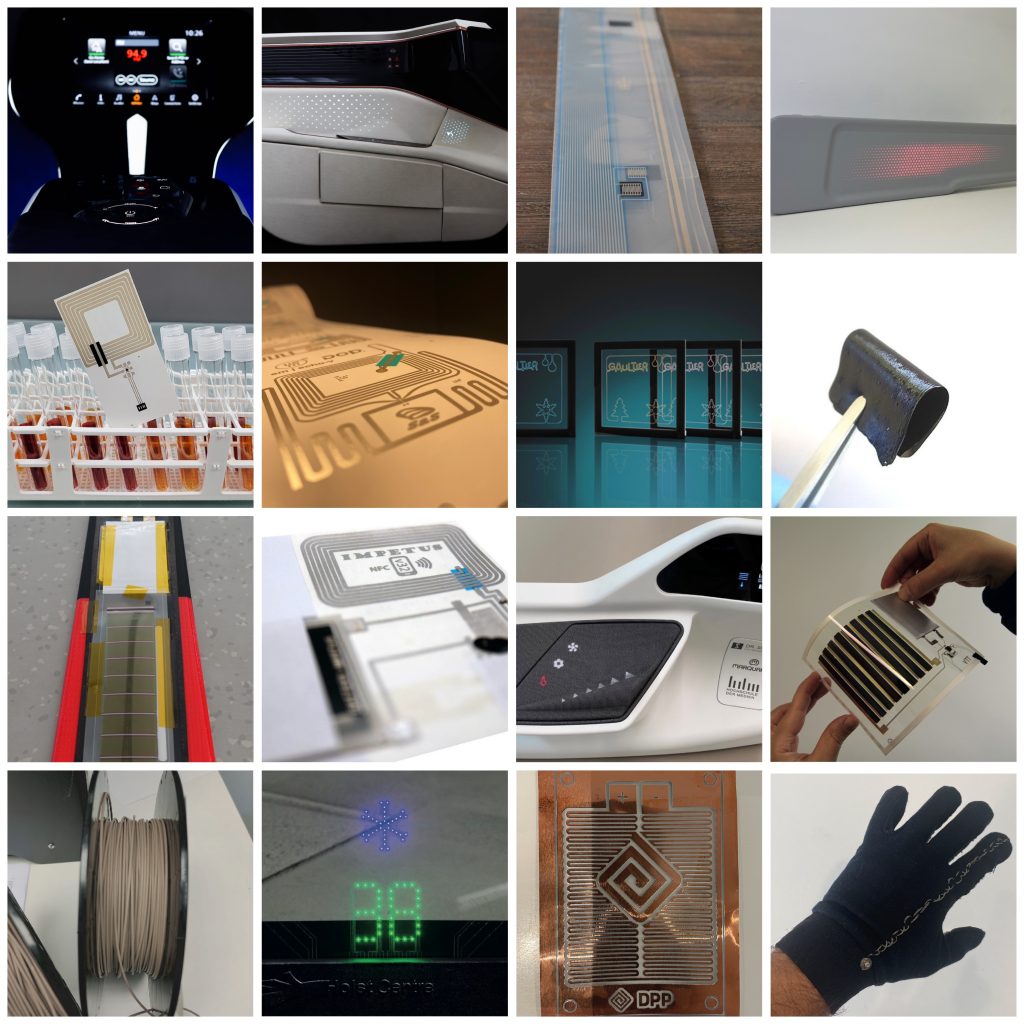

Purpose

- Enable embedded smartness and intelligence for IoT, identification and sensing applications

- Integration and manufacturing process development for double-sided flexible systems

- Enable space reduction and hide/embed features on the backside

- Enable user interface on both sides for increasing the opportunities in product design

Target Group

- IoT

- Printing and Packaging

- Smart Buildings

Benefits

- Roll-to-roll manufacturing process of through-substrate vias enabled double-sided printed electronics

- Versatility for various designs, dimensions and materials (substrate, inks)

Printed Electronics Components

- Conductive path

- Printed interconnection

- Printed perovskite PV