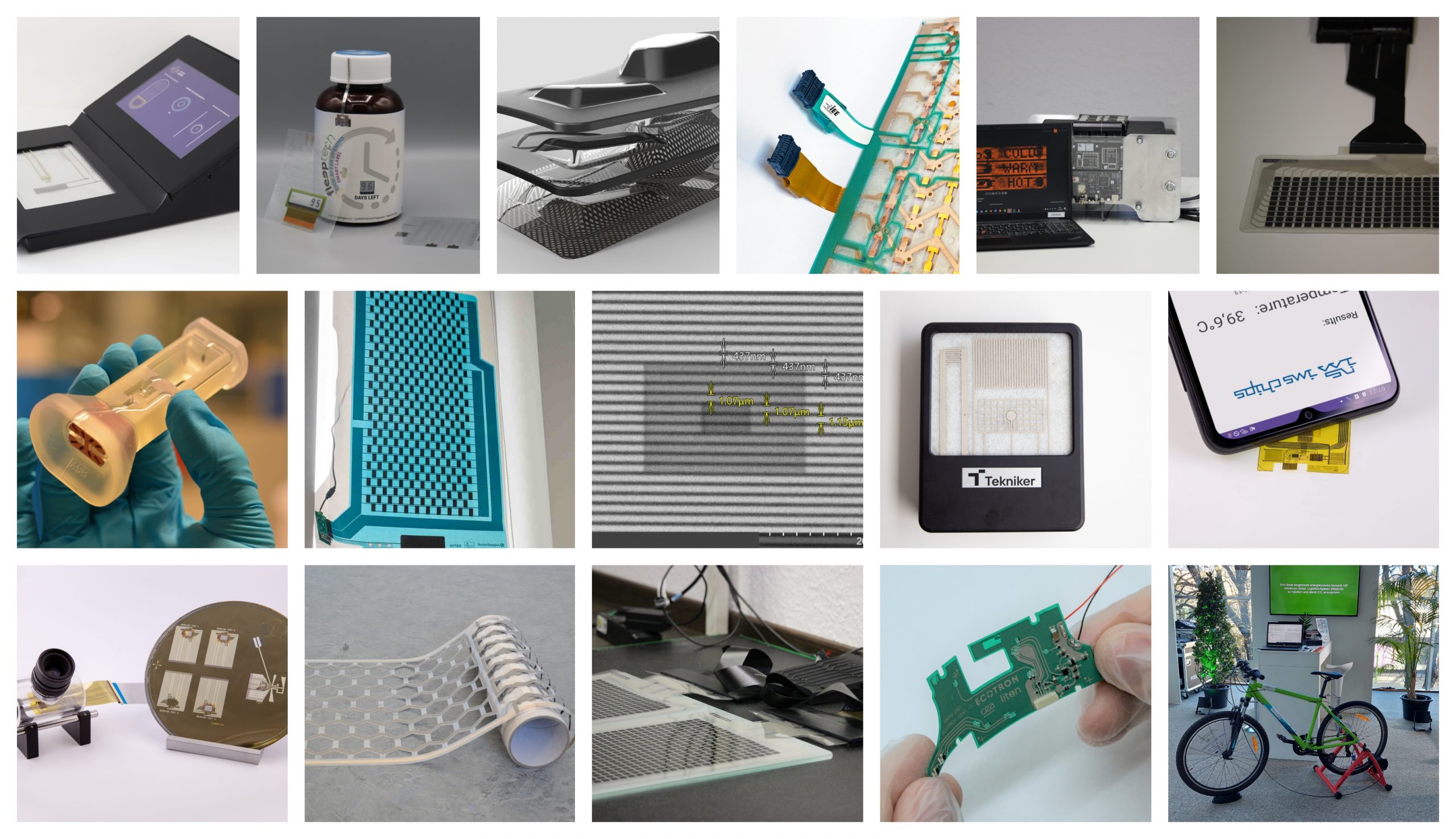

InnovationLab, Germany

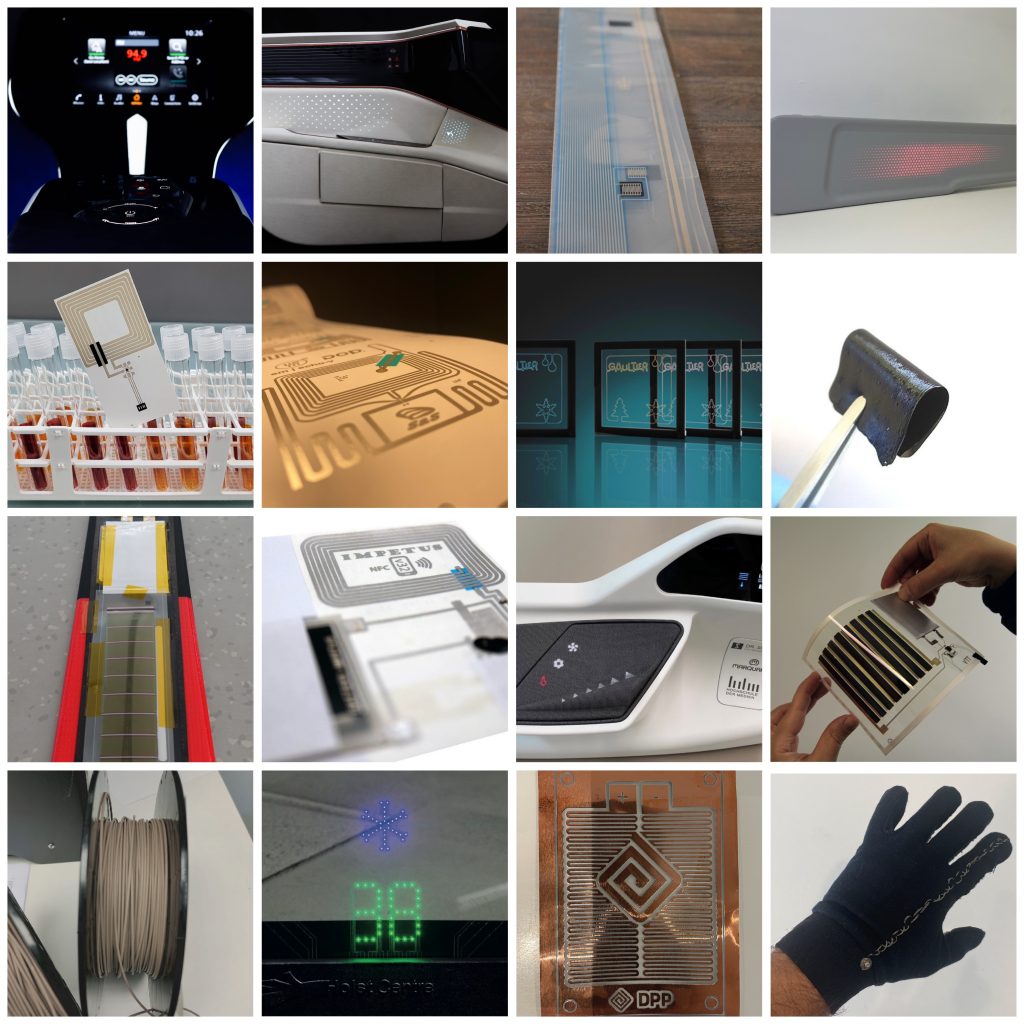

The demo by InnovationLab represents the surface of an arm-rest in a car with additional features for lighting as well as heating.

A printed and transparent heater structure is mounted under the cover of the armrest. In combination with a backlighting structure, lighting and heating are realised in one part. Classical heating in cars is a waste of energy if energy has to be used in addition and can not simply be taken out of the warm motor (especially in electrically driven cars). This can be overcome by heating surfaces near by the passengers. In best case, this is done in combination with other functions to save cost and assembly effort an allow nicely formed user interfaces and/or control units in automotive or related applications.

Purpose

- To show the combination between lighting and heating

- Drastically reducing the number of parts in an assembly

- Increase energy-efficiency by heating surfaces near by the passengers

Target Group

- Automotive

- Smart Buildings

- Consumer Electronics

- Printing and Packaging

Benefits

- Allows for easy integration as well as a competitive prizing

- Solves the combination between heating and lighting functionality in one part

- Increase energy-efficiency

Printed Electronics Components

- Conductive path

- Printed heater

- Printed capacitive switch

- Printed interconnection